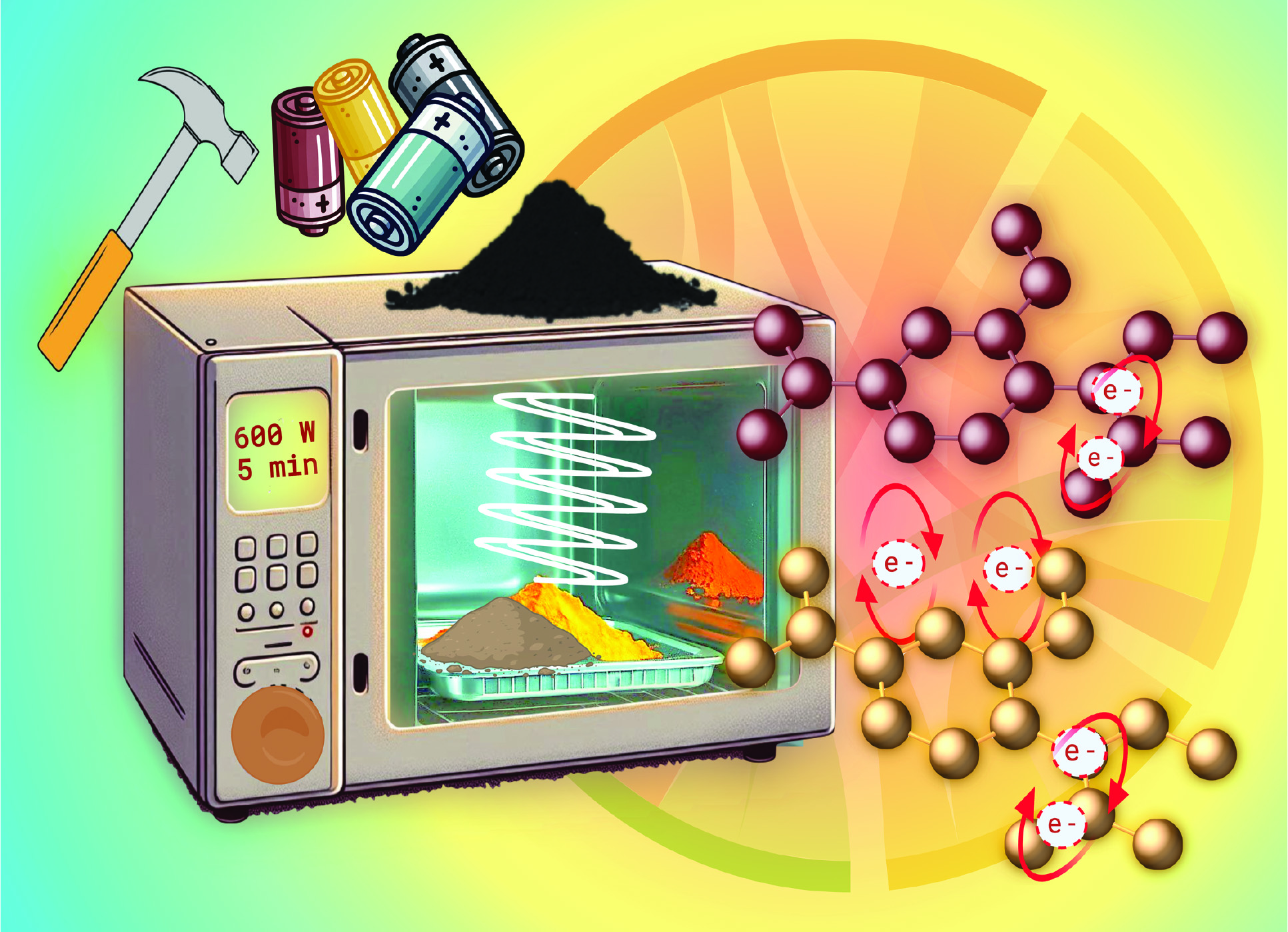

Lithium-ion batteries, present in many everyday objects, from smartphones to electric cars, have become essential in pursuing energy transition goals. They contain strategic metals such as lithium, cobalt, nickel, and manganese, which are on the list of critical materials at risk of depletion by 2030. The availability of these metals, whose demand will grow exponentially in the coming years, is highly localized in some areas of the Earth and their extraction often requires very energy-intensive processes with high water consumption. Over the years, several processes have been proposed for recovering metals from exhausted lithium-ion batteries, but they are characterized by a significant environmental impact. The proposed recovery process involves a microwave-based method that allows very high temperatures, above 600 °C, to be reached in a few minutes. This process, applied to a lithium-cobalt oxide battery, allows effective recovery of lithium (> 80%) with treatment in a microwave oven at 600 W for 5 min. The published study demonstrates that, for the same treatment time, the recovery efficiency increases with the increase in the treated mass, reaching high temperatures more easily in a short time.

The research team of the University of Brescia, composed of Prof. Elza Bontempi, Prof. Laura Eleonora Depero, Alessandra Zanoletti, Antonella Cornelio, Bianca Maria Bresolin, Matteo Scaglia, Alessandro Bonometti and Sonia Calce, is working specifically on the following projects, which aim to improve the recovery of critical metals from exhausted batteries, minimizing the environmental impact:

- Tech4Lib (Low-energy technologies for circular economy of spent lithium-ions batteries based on enhanced microwave effects), funded by Fondazione Cariplo and InnovFin Equity, with the support of the European Union under Horizon 2020 and the European Fund for Strategic Investments (EFSI), established under the Investment Plan for Europe. This project proposes a microwave-based method, capable of reaching high temperatures (over 600 °C) in a few minutes, achieving effective lithium recovery (> 80%) with a microwave oven treatment at 600 W for only 5 minutes.

- Amelie (New approaches to recovery criticAl MEtals from spent LIthium-ions battEries), funded by Next-GenerationEU (Italian PNRR – M4 C2, Invest 1.3 – D.D. 1551.11-10-2022, PE00000004) within the MICS extended partnership (Made in Italy – Circular and Sustainable), which focuses on new approaches for recovering critical metals from spent lithium-ion batteries.

The team’s research contributes to the United Nations Sustainable Development Goals (SDGs): building resilient infrastructure and promoting innovation (SDG 9), supporting industry in sustainable practices (SDG 11), and ensuring sustainable consumption and production patterns (SDG 12). Additionally, by reducing water-intensive metal mining and processing, the team contributes to efforts to ensure the availability and sustainable management of water and sanitation for all (SDG 6).